Application

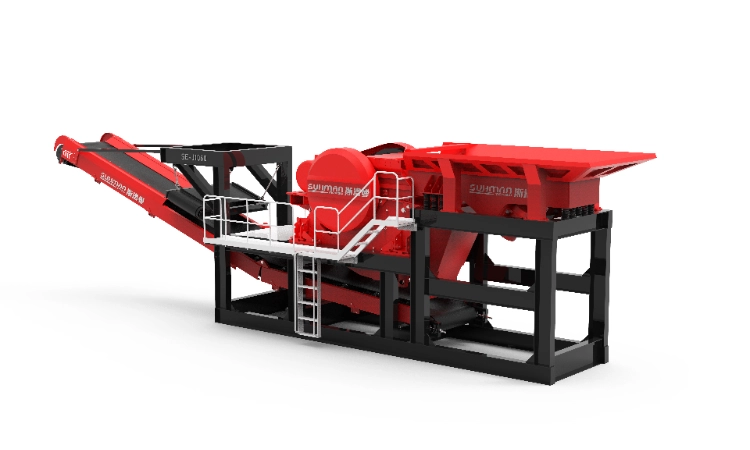

The Mobile Crushing and Screening Integrated Machine is widely used in various industries where flexibility and efficiency in material processing are essential. Its ability to combine both crushing and screening functions in a single, mobile unit makes it ideal for operations that require high mobility and quick setup.

In the mining industry, this machine is used for the extraction and processing of ores and rocks. It can efficiently crush and screen materials on-site, minimizing transportation costs and time. For example, in large-scale mining operations, the machine can reduce the size of extracted materials and sort them based on specific sizes required for further processing or transportation. This eliminates the need for multiple machines and reduces the overall operational complexity.

In construction and demolition, the mobile unit is frequently deployed to crush and recycle concrete, asphalt, and other building materials directly at demolition or construction sites. The machine crushes large chunks of material and screens them into reusable aggregates, which can then be used for new construction projects. This not only reduces waste but also contributes to sustainable construction practices by reusing materials on-site.

The aggregate production industry also benefits from this mobile machine. It is used to process gravel, sand, and crushed stone, providing high-quality aggregates for the production of concrete and asphalt. With its ability to adjust to different crushing and screening needs, it helps meet varying customer specifications for material size and quality.

Moreover, the machine’s mobility allows it to be used in temporary or remote locations where traditional stationary equipment might not be feasible. Its adaptability and efficiency make it an essential tool in industries such as mining, construction, and recycling.

Product Parameter

| Project | Name | SF-580D-S |

| Feed section | Feeding capacity (t/h) | 300 |

| Hopper volume (m³) | 6 | |

| Power (kw) | 4.5×2 | |

| Feeder size (length x width) (mm) | 3950x1460 | |

| Feeding height (mm) | 4000 | |

| Crusher | Crusher model | 1315 |

| Feed inlet size (length x width) (mm) | 1540x1100 | |

| Maximum feed particle size (mm) | <700 | |

| Adjustment range of discharge port (mm) | 300-500\0-150 | |

| Crusher weight (t) | 23 | |

| Crusher power (kw) | 315 | |

| Main belt | Length x Width (mm) | 11500×1600 |

| Unloading height (mm) | 3530 | |

| Power (kw) | 9.5×2 | |

| Belt for finished materials | Length x Width (mm) | 5800×1350 |

| Unloading height (mm) | 2580 | |

| Power (kw) | 7.2×2 | |

| Return material hanging sieve | Length x Width (mm) | 5600×2160 |

| Power (kw) | 3.7×2 | |

| Number of sieve layers (layers) | 2 | |

| Screen size (mm) | 4600×1540 | |

| Transition belt | Length x Width (mm) | 1750×770 |

| Power (kw) | 3 | |

| Side conveyor belt | Length x Width (mm) | 6500×970 |

| Power (kw) | 5.5 | |

| Return conveyer belt | Length x Width (mm) | 7200×970 |

| Power (kw) | 5.5 | |

| De-ironing separator | Length x Width (mm) | 2100×910 |

| Power (kw) | 3 | |

| Complete machine | Track chassis model | LDZ60-4037 |

| Engine power (kw) | 100 | |

| Whole machine weight (t) | 58 | |

| Machine processing capacity (t/h) | 180-230 | |

| Total power of crushing work (kw) | 383.4 | |

| Working dimensions (length, width, height/mm) | 17652×7700×4100 | |

| Transportation dimensions (length, width, height/mm) | 17652×3500×3900 |