Mining operations rely heavily on various types of crushing equipment to process raw materials efficiently. Among these, jaw crushers play a critical role in the initial stages of material processing. Jaw crushers are essential tools used to break down large rocks into smaller, more manageable pieces, making them a cornerstone in the mining, construction, and recycling industries. In this article, we will explore how jaw crushers contribute to efficient mining operations, the different types of jaw crushers, and the latest advancements that improve their performance.

What is a Jaw Crusher?

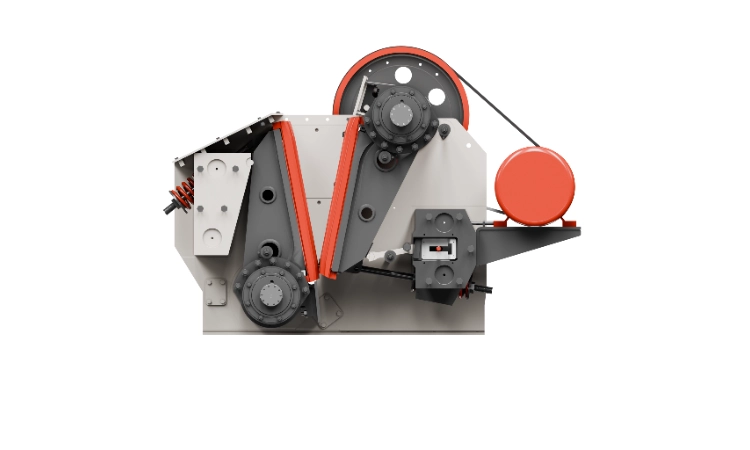

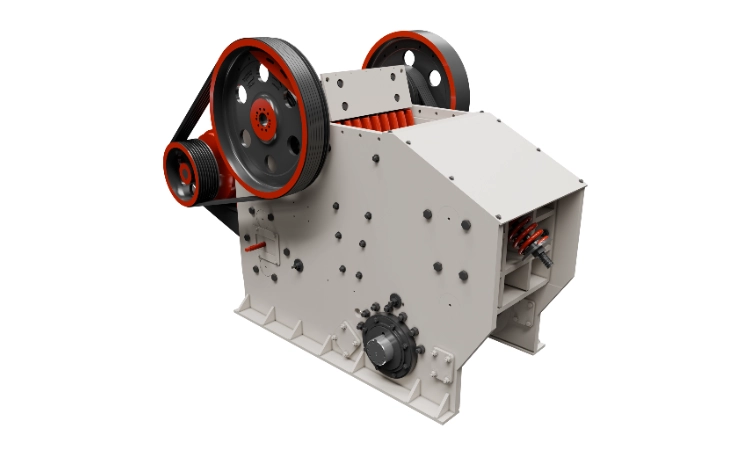

A jaw crusher is a type of machine that reduces large rocks into smaller fragments by using a compressive force. Typically used in the primary crushing stage, jaw crushers break down raw material into a size that is manageable for further processing. The basic principle involves the two jaw plates — one stationary and one movable — that form a V-shaped opening. As the movable jaw moves towards the stationary one, material is trapped and crushed.

Key Components of a Jaw Crusher:

- Feed opening: The area where materials are fed into the crusher.

- Moving jaw: The part that moves back and forth to crush the material.

- Fixed jaw: The stationary part of the crusher.

- Pitman: A component that transmits the motion to the movable jaw.

- Toggle plates: Provide the mechanical advantage required for crushing.

Types of Jaw Crushers

There are different types of jaw crushers, each designed for specific applications. The two most common types are:

1. Single-Toggle Jaw Crusher

- Mechanism: A single toggle jaw crusher uses a single moving jaw to crush materials, with a lever acting as a pivot point.

- Advantages: Simpler construction, less complex mechanism, and more efficient at higher speeds.

- Ideal for: Primary crushing of hard rocks and materials.

2. Double-Toggle Jaw Crusher

- Mechanism: In a double-toggle jaw crusher, two moving jaws operate. One jaw moves horizontally, while the other moves vertically.

- Advantages: Higher crushing efficiency and the ability to handle tougher materials.

- Ideal for: Crushing materials with higher abrasiveness.

| Feature | Single-Toggle Jaw Crusher | Double-Toggle Jaw Crusher |

|---|---|---|

| Crushing Efficiency | Higher at higher speeds | Better for harder materials |

| Maintenance | Lower maintenance needs | Requires more maintenance |

| Power Consumption | Lower | Higher |

Importance of Jaw Crushers in Mining Operations

1. Efficient Material Size Reduction

Jaw crushers play an important role in reducing large rocks into smaller, manageable sizes. Primary crushers, like jaw crushers, are responsible for handling the first stage of size reduction. The efficiency of this process is crucial for the subsequent steps in material handling, as the size of the material directly affects the efficiency of secondary and tertiary crushers.

By breaking down large rocks into smaller pieces, jaw crushers reduce the wear and tear on secondary crushers, as they do not need to handle overly large materials. This leads to increased efficiency throughout the entire crushing circuit.

2. High Throughput Capacity

A significant advantage of jaw crushers is their ability to process large amounts of material in a relatively short amount of time. This high throughput capacity is critical in mining operations where large volumes of raw materials must be processed efficiently.

Jaw crushers typically provide high reduction ratios, allowing operators to achieve the desired size of material in one pass. The efficient crushing action reduces the need for multiple stages of size reduction, saving both time and resources.

3. Energy Efficiency

Compared to other crushing equipment, jaw crushers are relatively energy-efficient. The design of jaw crushers is optimized to provide effective material crushing with lower power consumption. Energy savings in mining operations can lead to significant cost reductions, especially in large-scale operations that require continuous, high-volume material processing.

4. Flexibility in Material Processing

Jaw crushers are capable of handling a wide variety of materials, ranging from hard rocks to more friable materials. The ability to crush materials like granite, limestone, and other hard rocks, as well as softer materials like clay and shale, makes jaw crushers versatile and adaptable to different mining needs.

Additionally, jaw crushers can be used in combination with other crushers and equipment, such as cone crushers and impact crushers, to create a multi-stage crushing process that ensures maximum efficiency.

5. Reliability and Durability

Mining operations often take place in harsh environments where machinery must operate continuously under heavy loads. Jaw crushers are designed to withstand these conditions, offering reliable and durable performance. With proper maintenance and care, jaw crushers can provide years of reliable service, reducing downtime and increasing productivity.

6. Cost-Effectiveness

The relatively low cost of jaw crushers compared to other types of crushers makes them an attractive option for mining operations. Not only is the initial investment lower, but the maintenance and operational costs are also manageable. The efficiency of jaw crushers in terms of throughput, energy consumption, and durability further contributes to their cost-effectiveness over the long term.

The Latest Technological Advancements in Jaw Crushers

The design and functionality of jaw crushers have continuously evolved, leading to improvements in their efficiency and performance. Some of the most notable recent advancements include:

1. Hydraulic Systems for Adjustments

Many modern jaw crushers come equipped with hydraulic systems that allow for quick adjustments to the size of the output material. Hydraulic toggles provide a more efficient way to adjust the gap between the fixed and moving jaws, enabling faster operation and improved material sizing.

2. Advanced Wear-Resistant Materials

To extend the lifespan of jaw crushers and reduce downtime due to wear, manufacturers are now using advanced wear-resistant materials for key components like the jaw plates and liners. This helps to ensure that the machine maintains its performance even under extreme working conditions.

3. Automation and Remote Monitoring

Incorporating automation and remote monitoring technologies allows for more efficient operation and maintenance of jaw crushers. Operators can monitor the performance of the machine in real-time, adjust settings remotely, and perform predictive maintenance. This leads to reduced downtime and more proactive equipment management.

4. Improved Crushing Action

Newer jaw crushers are designed to enhance the crushing action, making them more efficient at breaking down material. Advanced crushing chamber geometry and jaw profile designs optimize the machine's ability to handle a wider range of materials with less wear and improved throughput.

Factors to Consider When Choosing a Jaw Crusher for Mining Operations

Selecting the right jaw crusher for your mining operation is critical to ensuring optimal performance. Several factors need to be considered, including:

1. Feed Size

Ensure that the jaw crusher you select can handle the size of the materials being fed into it. A crusher with a larger feed opening may be required for larger rocks.

2. Crushing Capacity

Choose a jaw crusher with the appropriate crushing capacity for your needs. It is important to ensure that the machine can handle the volume of material that needs to be processed.

3. Material Characteristics

The hardness, abrasiveness, and moisture content of the materials you plan to crush will affect the performance of the jaw crusher. Choose a machine that is capable of handling the specific type of material in your mining operation.

4. Maintenance and Support

Choose a manufacturer that offers reliable support and maintenance services. Regular maintenance is essential to ensure that your jaw crusher performs at its best.

Conclusion

Jaw crushers are essential in mining operations for efficient material size reduction, high throughput capacity, energy efficiency, and cost-effectiveness. With ongoing advancements in technology, jaw crushers have become more reliable, durable, and adaptable, offering significant benefits to mining companies. By choosing the right jaw crusher and utilizing modern technologies, mining operations can maximize efficiency and reduce operational costs.

As a jaw crusher manufacturer and supplier, we offer high-quality new and used jaw crushers for sale or rent. Our jaw crushers are designed to handle a wide variety of materials and are built to last. If you are looking for reliable and efficient crushing equipment for your mining operation, contact us today to learn more about our products and services.