Application

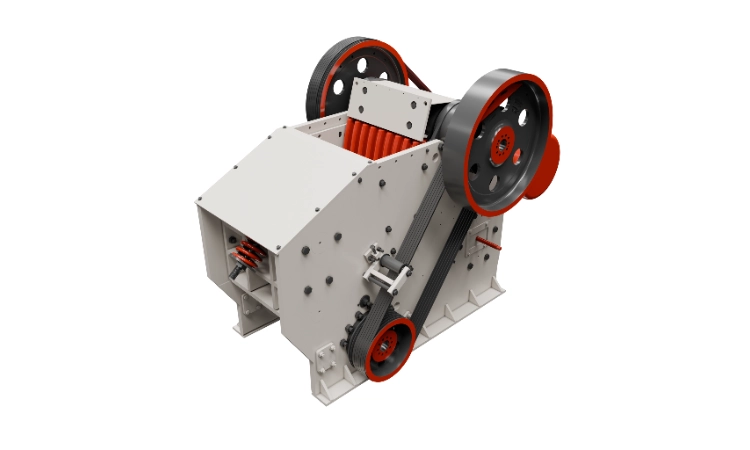

The Efficient and Multifunctional Modular Cone Crusher is widely used across various industries for its versatility, high performance, and ability to handle a range of materials. In the construction and aggregate industries, this crusher plays a crucial role in producing high-quality aggregates for road construction, concrete, and asphalt production. It efficiently processes hard rocks, such as granite, basalt, and limestone, into uniform, well-graded materials required for infrastructure projects.

In the mining industry, the cone crusher is invaluable for ore processing. It crushes hard ores like copper, iron, and gold, reducing them to the necessary size for further refinement. The crusher's ability to handle varying feed sizes and its reliable, high-output capabilities make it ideal for mining operations that require consistent and efficient material processing.

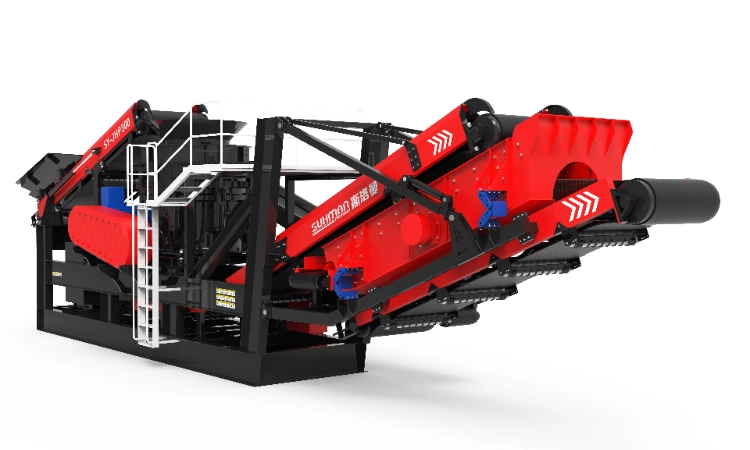

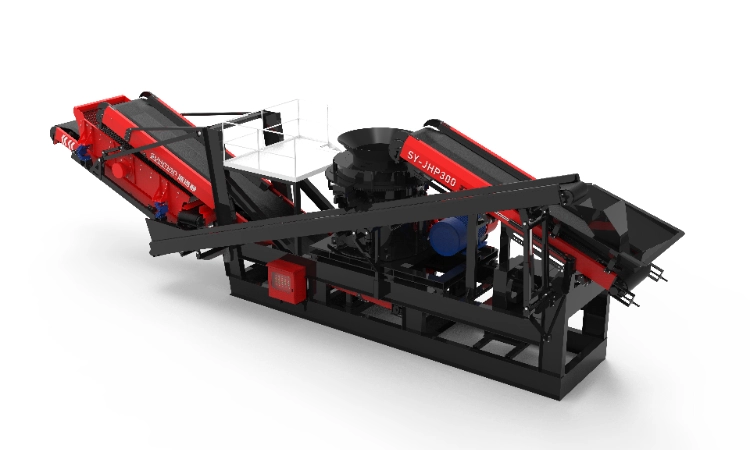

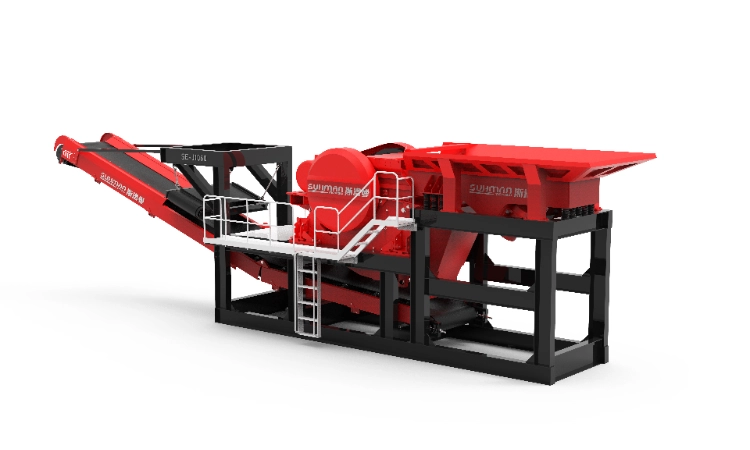

The modular nature of the cone crusher also makes it suitable for mobile applications, offering flexibility for remote or temporary construction sites. It can be quickly transported and set up for projects requiring high mobility, like roadworks or mining in hard-to-reach areas.

Additionally, the crusher is frequently used in the recycling industry, where it processes demolition debris, concrete, and asphalt. By reducing these materials into usable aggregates, the cone crusher supports sustainable construction practices and helps divert waste from landfills.

Overall, the Efficient and Multifunctional Modular Cone Crusher’s adaptability, low maintenance needs, and energy efficiency make it a preferred choice for a wide range of applications, from large-scale mining operations to smaller construction and recycling projects.

Product Parameter

| Parameter | Specification |

|---|---|

| Model | Modular Cone Crusher |

| Material Processed | Hard rocks (granite, basalt, limestone), ores (copper, iron, gold), construction debris, concrete, asphalt |

| Feed Size | Up to 450 mm (varies depending on model) |

| Capacity | 100-500 tph (varies depending on model and material) |

| Max Product Size | 0-40 mm (adjustable based on requirements) |

| Cone Diameter | 900 mm to 2200 mm (varies by model) |

| Motor Power | 75 kW to 400 kW (depending on model) |

| Crushing Chamber Design | Customizable cone design for fine or coarse crushing |

| Discharge Opening Adjustment | Hydraulic or manual adjustment |

| Hydraulic System | Hydraulic adjustment, overload protection, and clamping system |

| Liner Material | High-chrome, wear-resistant steel |

| Weight | 20,000 kg to 60,000 kg (varies by model) |

| Dimensions (L x W x H) | 4.5 m x 3.2 m x 4.5 m (varies by model) |

| Transportability | Modular design for easy transport and mobility |

| Power Supply | Electric or diesel-powered options available |

| Maintenance | Easy access to components, reduced downtime due to efficient design |

| Applications | Mining, construction, aggregate production, recycling, roadworks |

| Automation | Automated control systems for efficiency and ease of operation |