Application

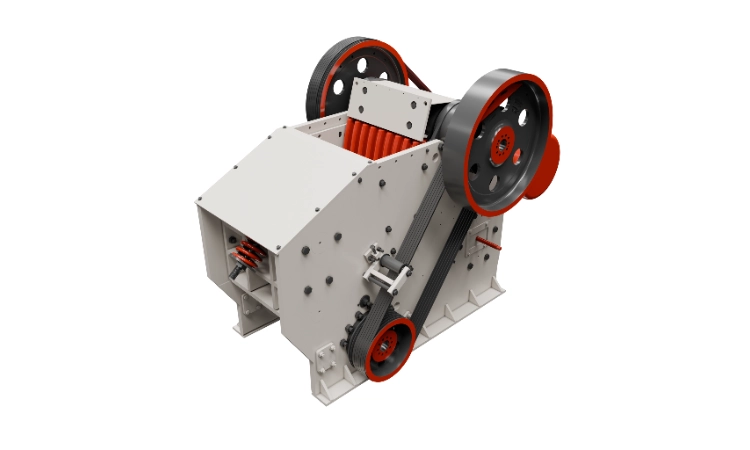

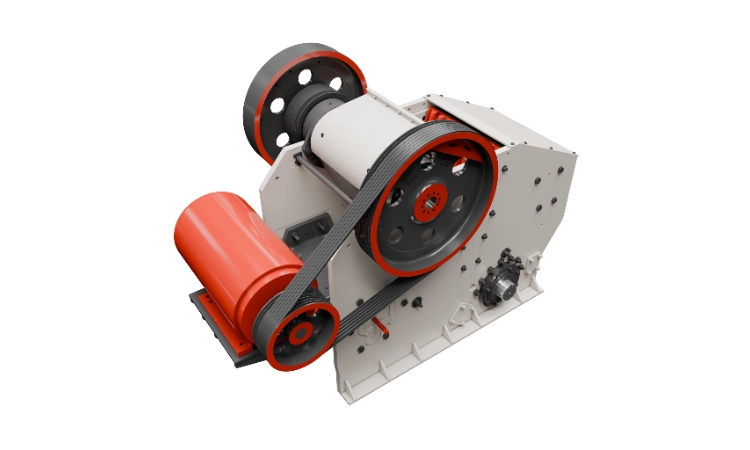

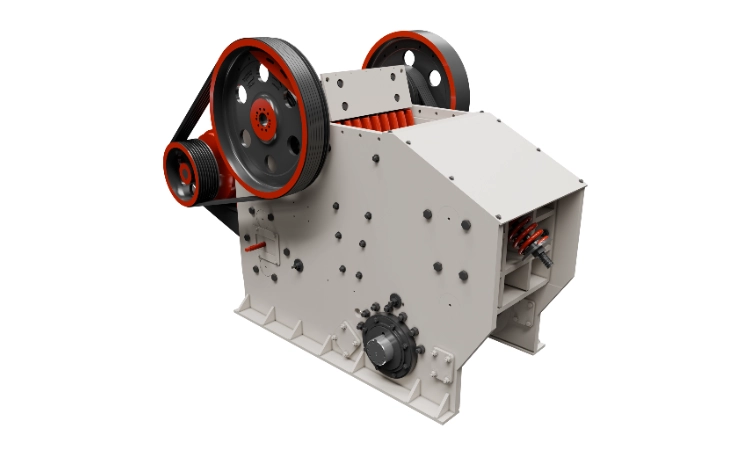

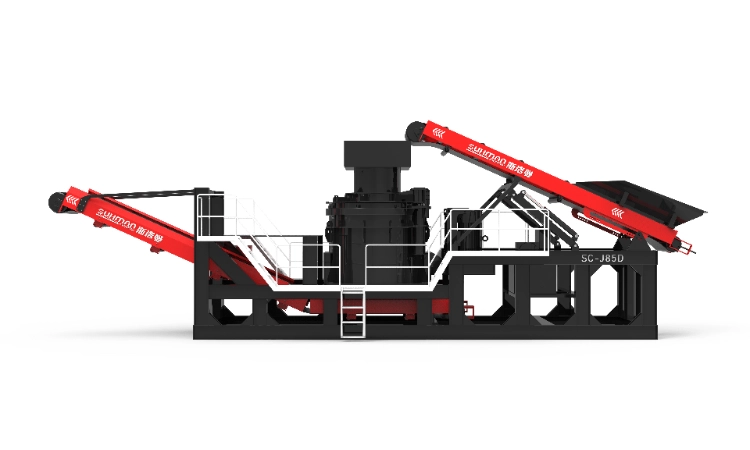

The Dual-core Jaw Crusher is primarily used in industries that require efficient, high-capacity crushing of tough materials. It is particularly suited for mining, where it processes hard rocks like granite, basalt, and quartz, efficiently breaking them down into smaller, manageable sizes for further processing. The dual-core design allows it to handle larger volumes of material compared to traditional crushers, making it ideal for large-scale mining operations.

In construction, the dual-core jaw crusher is widely used for producing aggregates, which are essential for the manufacture of concrete, asphalt, and other building materials. Its ability to crush hard materials makes it a valuable tool in road construction, demolition, and infrastructure projects.

The recycling industry also benefits from this crusher, as it can process concrete, asphalt, and other construction waste, turning it into reusable aggregates. This contributes to sustainable practices by reducing the environmental impact of construction waste.

Product Parameter

| Parameter | Specification |

|---|---|

| Model | DC-JC1000, DC-JC1200, DC-JC1500 (example) |

| Crushing Capacity | 100-1500 tons per hour |

| Feed Opening Size | 600mm x 900mm to 1000mm x 1200mm |

| Discharge Size | 40mm - 150mm |

| Motor Power | 90kW - 250kW |

| Engine Type | Diesel, Electric (Hybrid options available) |

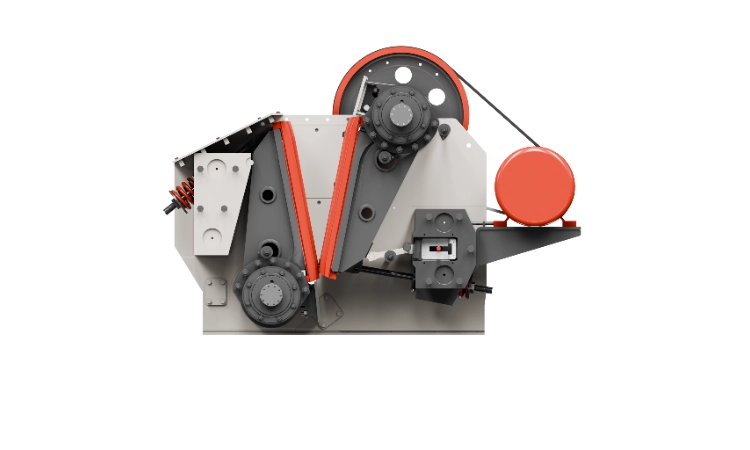

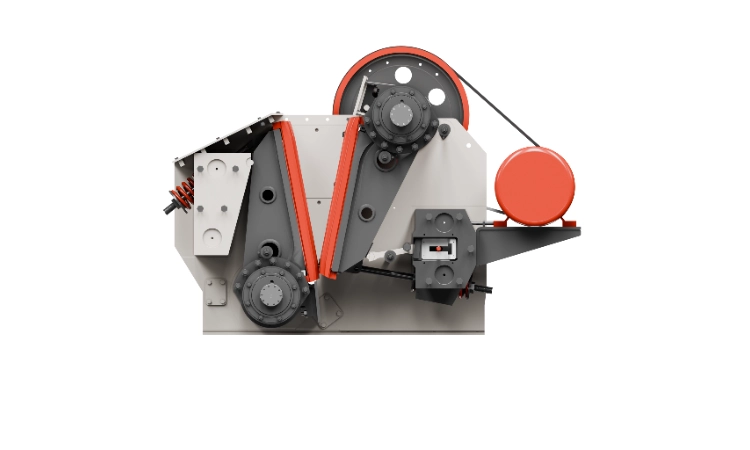

| Jaw Type | Dual-core (Two Crushing Chambers) |

| Overall Dimensions (L x W x H) | 13,000mm x 2,800mm x 4,200mm |

| Weight | 30-55 tons (depending on model) |

| Max Feed Size | Up to 1000mm |

| Throughput | 50-500 tph (depending on material and model) |

| Jaw Crusher Type | Single Toggle or Double Toggle |

| Crushing Force | 250-350 tons |

| Hydraulic System | Adjustable discharge and jaw movement |

| Adjustment Method | Hydraulic or Mechanical |

| Max Crushing Efficiency | Increased due to dual-core design |