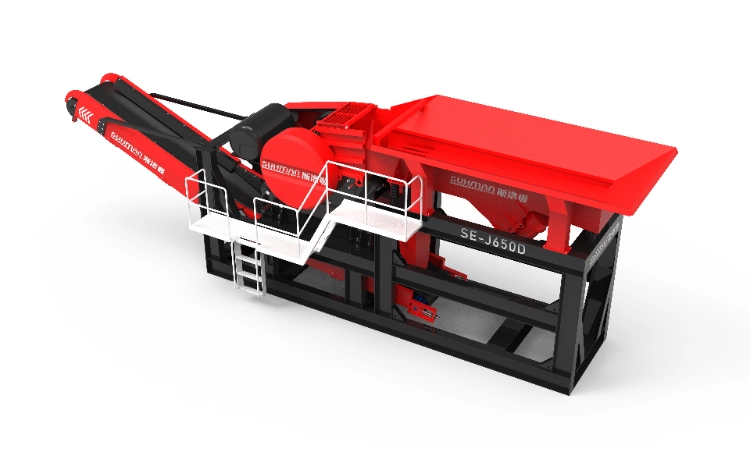

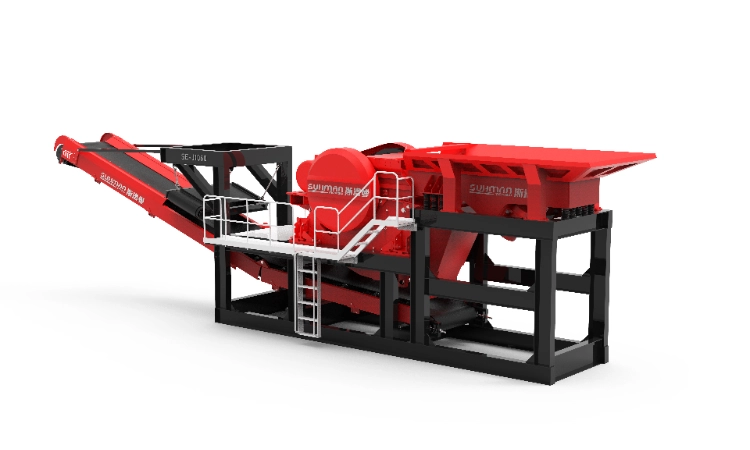

Application

The Efficient Mini Modular Jaw Crusher is widely used in various industries due to its versatility and compact design. It is primarily applied in mining, construction, and recycling operations for primary crushing of materials such as ores, rocks, and concrete debris. The crusher is ideal for small-scale operations, offering efficient size reduction for materials with a maximum feed size of up to 150 mm. It can be used in aggregate production, allowing for the production of different particle sizes to meet various project requirements. Additionally, the modular design makes it easy to transport, install, and maintain, providing a flexible solution for both fixed and mobile crushing applications. The crusher is also suitable for use in demolition sites and recycling plants, helping to reduce waste and recycle construction materials effectively. Its efficient performance and low energy consumption make it a cost-effective choice for small to medium-sized operations.

Product Parameter

| Parameter | Specification |

|---|---|

| Model | EMJ-1000 (Example model) |

| Feed Size | 100 mm (Max) |

| Discharge Size | 10-50 mm (Adjustable) |

| Capacity | 30-80 tons per hour |

| Motor Power | 15-30 kW |

| Jaw Plate Material | High Manganese Steel |

| Crushing Ratio | 6:1 to 8:1 |

| Frame Material | Steel (Modular design) |

| Weight | 1,500-2,500 kg (Depending on model) |

| Dimensions (L x W x H) | 2,000 x 1,200 x 1,500 mm (Varies by model) |

| Max Feed Size | 150 mm |

| Drive Type | Electric Motor |

| Discharge Opening Adjustment | Hydraulic or Manual |

| Application | Mining, construction, recycling, aggregate production |

| Safety Features | Overload protection, dust suppression system |