Application

The tracked cone crusher is mainly used for the following purposes:

Mining industry: In the mining of metal and non-metal ores, it is used to finely grind the extracted ore to provide suitable particle size raw materials for subsequent beneficiation operations. For example, in mines such as gold, copper, and iron, cone crushers can crush ores to the desired particle size to improve the efficiency and effectiveness of mineral processing.

Sand production line: As an important equipment in the sand production process, it cooperates with other equipment to produce high-quality machine-made sand.

Production of building aggregates: crushing large stones into particle sizes that meet the standards for building aggregates, used for the production of building materials such as concrete and asphalt mixtures. In large aggregate processing plants, cone crushers are often one of the key crushing equipment.

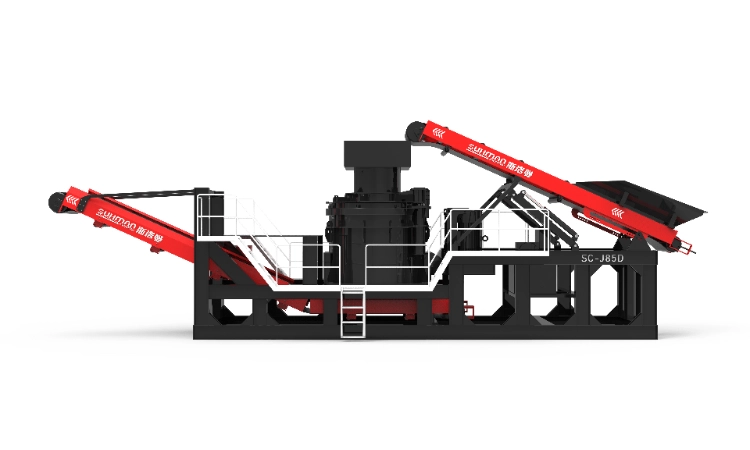

Product Parameter

| Project | Name | HP300 |

| Feeding equipment | Feeding capacity (t/h) | 200 |

| Hopper volume (m³) | 3 | |

| Feeding belt | Length x Width (mm) | 4500×1350 |

| Feeding height (mm) | 3000 | |

| Power (KW) | 7.5×2 | |

| crusher | cone crusher | HP300 |

| Maximum feed particle size (mm) | 210 | |

| Adjustment range of discharge port (mm) | 30-50 | |

| Crusher weight (t) | 18 | |

| Crusher power (KW) | 250 | |

| Main belt | Length x Width (mm) | 10930×1600 |

| Unloading height (mm) | 3570 | |

| Power (KW) | 9.2×2 | |

| Belt for finished materials | Length x Width (mm) | 5000×1350 |

| Unloading height (mm) | 2650 | |

| Power (KW) | 5.5×2 | |

| Return material hanging sieve | Hanging sieve size (mm) | 4600×2160 |

| Power (KW) | 5.5 | |

| Screen size (mm) | 4000×1540 | |

| Transition belt | Length x Width (mm) | 2000×770 |

| Power (KW) | 3 | |

| Return conveyer belt | Length x Width (mm) | 8930×770 |

| Power (KW) | 5.5 | |

| Complete machine | Track chassis model | LDZ55-3657 |

| Engine power (KW) | 100 | |

| Whole machine weight (t) | 48 | |

| Machine processing capacity (t/h) | 200-300 | |

| Total power of crushing work (KW) | 329.9 | |

| Working dimensions (length, width, height/mm) | 18000×7600×4000 | |

| Transportation dimensions (length, width, height/mm) | 16800×3650×3950 |