Application

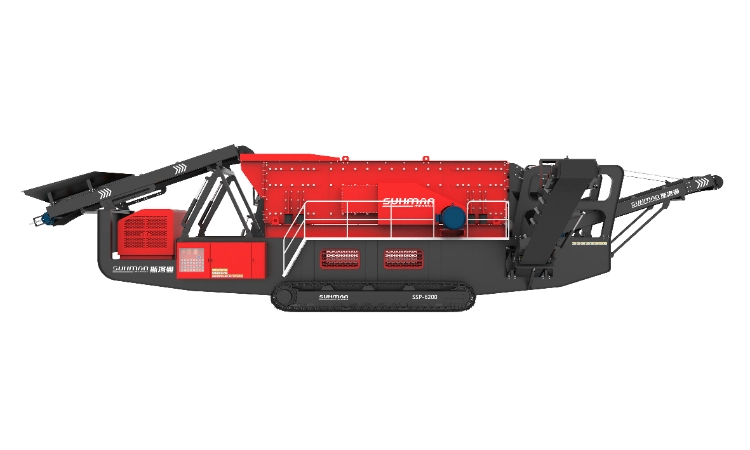

The Highly Efficient Horizontal Screener is widely used across various industries where precise material separation and high throughput are essential. One of its key applications is in the mining industry, where it is used to separate fine particles from crushed ores or aggregates. The horizontal motion ensures uniform material distribution across the screen, which leads to higher efficiency in sorting minerals into specific size fractions, aiding in subsequent processes like further crushing or refining.

In the construction and aggregate industry, the horizontal screener is used to sort sand, gravel, and crushed stone into different grades. This ensures that only materials of the right size are used in concrete production, road construction, or other building projects, improving the quality of the final product.

The recycling industry also benefits from this technology. The horizontal screener effectively sorts and separates materials such as plastics, metals, glass, and other recyclable materials from waste streams. Its efficiency in handling a mix of materials helps increase recycling rates, promoting sustainability and reducing waste.

In industrial processing applications, the screener is used to separate powders, chemicals, and fine particles in sectors such as pharmaceuticals, food processing, and chemicals. The gentle yet effective screening action ensures the material remains intact, without excessive degradation or contamination.

Its ability to handle large volumes of fine material with high accuracy and minimal maintenance makes the Highly Efficient Horizontal Screener an invaluable tool across these industries. Its design ensures maximum uptime and superior screening performance, even in challenging conditions.

Product Parameter

| Project | Description | SSP-6200 | |

| 1 | Feeding equipment | Hopper volume(m³) | 5 |

| 2 | Feed capacity (t/h) | 300-500 | |

| 3 | Power of Feeder | 11 | |

| 4 | Vibrating screen | Screen size (length x width)(mm) | 6200×1930 |

| 5 | Maximum feeding granularity(mm) | 100 | |

| 6 | Processing capacity(t/h) | 300-500 | |

| 7 | Power(kw) | 15kw×3 | |

| 8 | The number of screen layer (layer) | 3 | |

| 9 | Feeding belt | Width/length (mm) | 1000×20150 |

| 10 | Power(kw) | 11 | |

| 11 | Side belt conveyor 1 | Width/length (mm) | 550×14300 |

| 12 | Discharge height(mm) | 2800 | |

| 13 | Power(kw) | 5.5 | |

| 14 | Side belt conveyor2 | Width/length (mm) | 550×14300 |

| 15 | Discharge height(mm) | 2800 | |

| 16 | Power(kw) | 5.5 | |

| 17 | Side belt conveyor 3 | Width/length (mm) | 550×9800 |

| 18 | Discharge height(mm) | 2600 | |

| 19 | Power(kw) | 5.5 | |

| 20 | Belt conveyor under screen | Width/length (mm) | 1000×14500 |

| 21 | Discharge height(mm) | 3200 | |

| 22 | Power(kw) | 7.5 | |

| 23 | Track system | Country of origin | England |

| 24 | Brand | Strickland | |

| 25 | Specification length x width(mm) | 4000×400 | |

| 26 | Maximum inclination of walking (°) | 30 | |

| 27 | Walking speed(km/h) | 0.8-1.5 | |

| 28 | Accessories brand | Control System (electrical) | Chuan Ken |

| 29 | Walking system | Strickland | |

| 30 | Conveyor belt | Qingdao Global | |

| 31 | Hydraulic machinery | Bomke | |

| 32 | The engine | CUMMINS | |

| 33 | Steel | Models | Q355B(Materials used for warships) |

| 34 | The whole machine | Weight(t) | 37t |

| 35 | Shipping dimensions(mm) | 14300×3630×3850 | |

| 36 | Working size(mm) | 13100×12000×5000 |