Application

The Mobile Impact Crusher for Sand Making is extensively used in various practical applications, particularly in the production of high-quality sand for construction and other industries. In construction, it is highly effective for crushing materials like granite, limestone, and basalt, producing sand that meets the strict requirements for concrete and mortar. The produced sand is ideal for making durable concrete with the right particle size and gradation.

In road construction, this mobile crusher provides a steady supply of fine aggregates for asphalt and road base materials. Its mobility allows it to be moved directly to the site, significantly reducing transportation costs and time spent on material handling.

The recycling industry also benefits from this crusher, as it can process waste materials such as concrete and asphalt into valuable sand, promoting sustainability by reducing landfill waste. The ability to produce usable sand from recycled materials directly at demolition or construction sites minimizes environmental impact.

Overall, the mobile impact crusher for sand making enhances operational efficiency by providing on-site material processing, reducing transportation costs, and producing high-quality sand for a wide range of construction and manufacturing needs.

Product Parameter

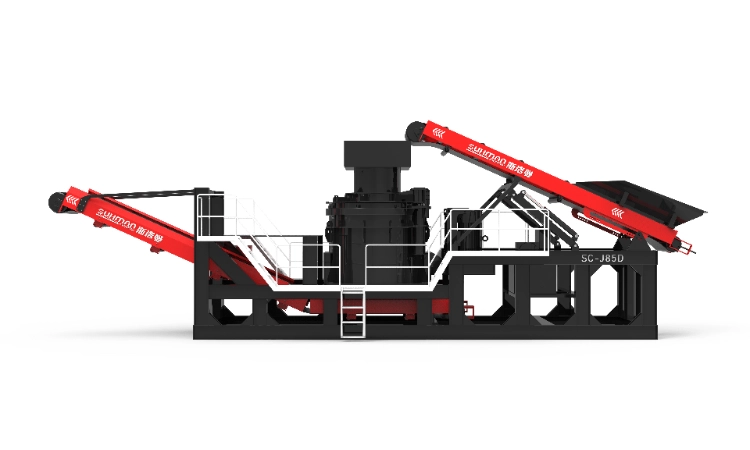

| Project | Description | SC-85D | |

| 1 | Feeding equipment | Hopper volume(m³) | 3 |

| 2 | Maximum feed size(mm) | 50 | |

| 3 | Feed capacity (t/h) | 150-350 | |

| 4 | Power of Feeder | 7.5(kw)×2 | |

| 5 | Impact Crusher For | Models | 85D |

| 6 | Maximum feed particle size (mm) | 50 | |

| 7 | Inlet size (length x width)(mm) | 1540×1000 | |

| 8 | Processing capacity(t/h) | 250 | |

| 9 | Power(kw) | 220 | |

| 10 | Weight(t) | 18 | |

| 11 | Main belt conveyor | Width/length (mm) | 1200×19100 |

| 12 | Discharge height(mm) | 3200 | |

| 13 | Power(kw) | 15 | |

| 14 | Track system | Country of origin | England |

| 15 | Brand | Strickland | |

| 16 | Specification length x width(mm) | 4500×500 | |

| 17 | Maximum inclination of walking (°) | 30 | |

| 18 | Walking speed(km/h) | 0.8-1.5 | |

| 19 | Power System (for single walking) | Models | QSB3.9-G3 |

| 20 | Fuel consumption (L/h) | 3.9 | |

| 21 | Power(kw) | 79 | |

| 22 | Tank volume(L) | 200 | |

| 23 | Emission standards | National III | |

| 24 | Power System -LRB-both oil and electricity) | Models | QSZ13-G11 |

| 25 | Brand | CUMMINS | |

| 26 | Fuel consumption (L/h) | ||

| 27 | Power(kw) | 512 | |

| 28 | Tank volume(L) | 600 | |

| 29 | Emission standards | National III | |

| 30 | Accessories brand | Control System (electrical) | Chuan Ken |

| 31 | Walking system | Strickland | |

| 32 | Conveyor belt | Qingdao Global | |

| 33 | hydraulic machinery | Bomke | |

| 34 | The engine | CUMMINS | |

| 35 | Steel | Models | Q355B(Materials used for warships) |

| 36 | The whole machine | Weight(t) | 37 |

| 37 | Shipping dimensions(mm) | 15000×3200×3800 | |

| 38 | Working size(mm) | 14400×3200×4300 |