Application

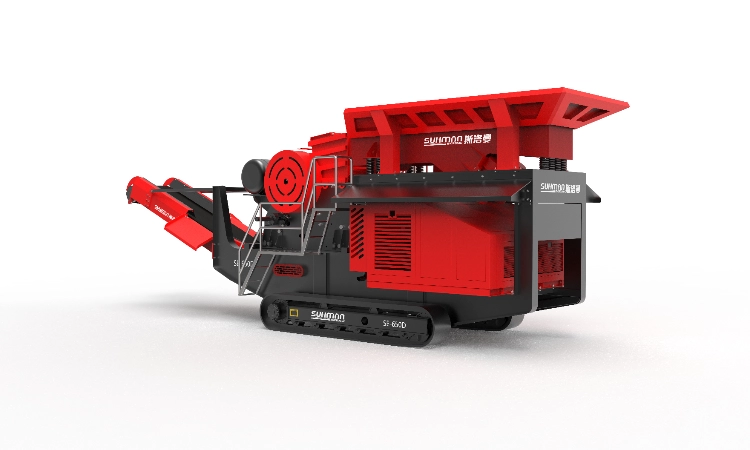

The High Cost-effectiveness Mobile Jaw Crusher Mini is highly versatile and widely used in various practical applications, particularly in construction, demolition, and mining industries. Its compact design and mobility make it ideal for operations that require on-site material processing, especially in areas where space is limited or access to large stationary equipment is difficult.

In construction and demolition, this mini jaw crusher is commonly used to crush concrete, bricks, asphalt, and other construction debris into smaller, reusable materials. It allows construction companies to recycle materials directly at the job site, reducing the need for hauling waste away and minimizing the environmental impact. The crushed material can be repurposed for new projects, such as road construction or foundation filling, offering a cost-effective solution for waste management and material reuse.

In mining, the mobile jaw crusher is used for primary crushing of rocks and ores. It processes hard materials into smaller pieces, which can then be further refined or processed at the site or transported for additional processing. The mobility of the unit ensures that it can be moved easily between different areas of a mine, enhancing efficiency and reducing downtime.

In road maintenance and quarrying, the High Cost-effectiveness Mobile Jaw Crusher Mini is used to produce aggregates for roadbeds, pavements, and other infrastructure projects. Its ability to operate in remote locations or on-site means that it can deliver the right-sized aggregates without the need for complex transport logistics.

Overall, this mobile jaw crusher provides a highly efficient, flexible, and cost-effective solution for many industries, improving productivity and reducing operational costs by enabling on-site crushing and material processing.

Product Parameter

| Project | Description | SE-650D | |

| 1 | Feeding equipment | Hopper volume(m³) | 4 |

| 2 | Feed height(mm) | 3500 | |

| 3 | Maximum feed size(mm) | 500 | |

| 4 | Size of feeder (length x width)(mm) | 3600×700 | |

| 5 | Feed capacity (t/h) | 50-130 | |

| 6 | Power of Feeder | 3kw×2 | |

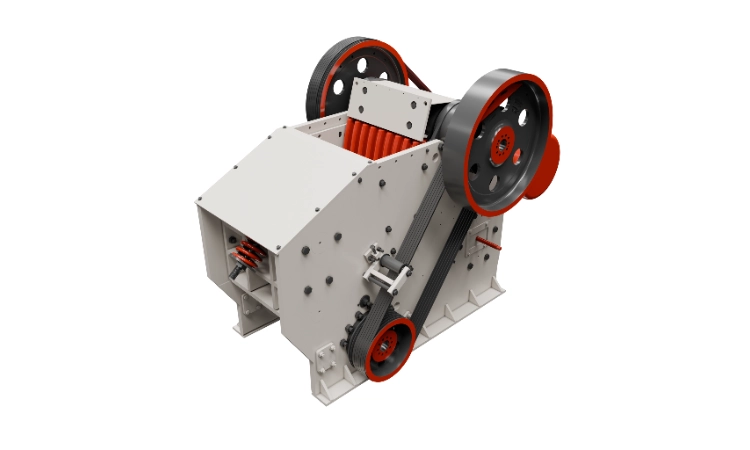

| 7 | Jaw Crusher | Models | 57 |

| 8 | Maximum feed particle size (mm) | 500 | |

| 9 | Inlet size (length x width)(mm) | 500×700 | |

| 10 | Processing capacity(t/h) | 50-130 | |

| 11 | Discharge particle size range(mm) | 0-100 | |

| 12 | Power(kw) | 75 | |

| 13 | Weight(t) | 10.1 | |

| 14 | Main belt conveyor | Width/length (mm) | 800×15100 |

| 15 | Discharge height(mm) | 2100 | |

| 16 | Power(kw) | 11 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 | |

| 22 | Side belt conveyor (Optional) | Width/length (mm) | / |

| 23 | Discharge height(mm) | / | |

| 24 | Power(kw) | / | |

| 25 | Track system | Country of origin | England |

| 26 | Brand | Strickland | |

| 27 | Specification length x width(mm) | 4160×500 | |

| 28 | Maximum inclination of walking (°) | 30 | |

| 29 | Walking speed(km/h) | 0.8-1.5 | |

| 30 | Power System (for single walking) | Models | QSB3.9-G3 |

| 31 | Fuel consumption (L/h) | 3.9 | |

| 32 | Power(kw) | 55 | |

| 33 | Tank volume(L) | 200 | |

| 34 | Emission standards | National III | |

| 35 | Power System -LRB-both oil and electricity) | Models | WP4.6ND138E310 (Weichai) |

| 36 | Fuel consumption (L/h) | ||

| 37 | Power(kw) | 100 | |

| 38 | Tank volume(L) | 500 | |

| 39 | Emission standards | National III | |

| 40 | Accessories brand | Control System (electrical) | Chuan Ken |

| 41 | Walking system | Strickland | |

| 42 | Conveyor belt | Qingdao Global | |

| 43 | hydraulic machinery | Bomke | |

| 44 | The engine | CUMMINS | |

| 45 | Steel | Models | Q355B(Materials used for warships) |

| 46 | The whole machine | Weight(t) | 30 |

| 47 | Shipping dimensions(mm) | 10000×2700×3500 | |

| 48 | Working size(mm) | 10000×2700×3500 |