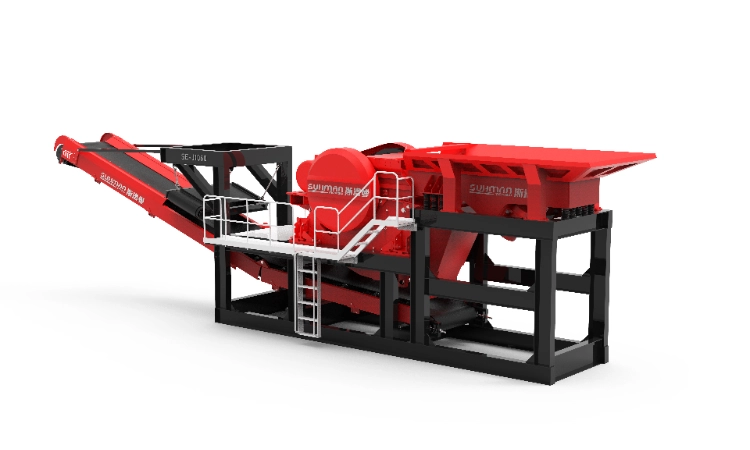

Application

The Widely Used Modular Jaw Crusher is widely applied across several industries for its efficiency in primary crushing tasks. In the mining sector, it is used to break down large rocks and ores into smaller, more manageable sizes, making the materials suitable for further processing, such as in milling or refining. Its ability to handle a variety of materials, including hard and abrasive rocks like granite, limestone, and basalt, makes it a valuable asset for mineral extraction operations.

In the construction industry, the modular jaw crusher is crucial for producing aggregates required in concrete and asphalt production. It efficiently reduces large chunks of stone into smaller, uniform-sized materials suitable for road construction, building foundations, and infrastructure projects.

Additionally, the crusher is highly effective in recycling applications, where it processes concrete, brick, and demolition debris. This helps in producing high-quality recycled aggregates that can be reused in construction, reducing waste and supporting sustainable building practices.

Its modular design ensures mobility, ease of installation, and quick setup, making it ideal for projects in remote or temporary locations. The jaw crusher's versatility and performance make it a preferred choice for these industries.

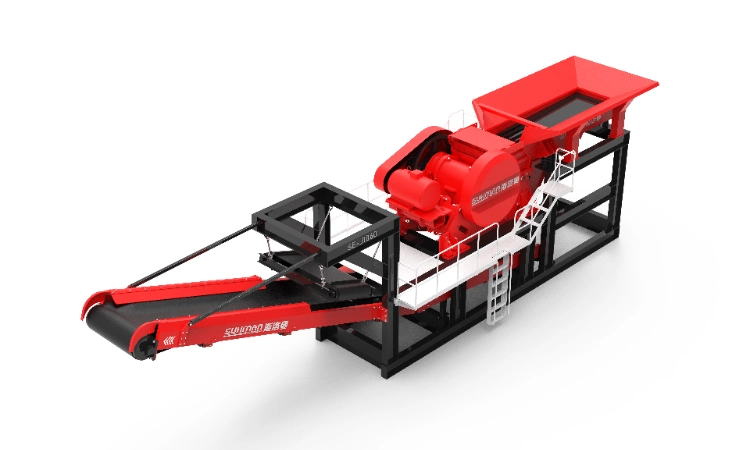

Product Parameter

| Project | Description | SE-J1060 | |

| 1 | Feeding equipment | Hopper volume(m³) | 5 |

| 2 | Feed height(mm) | 3800 | |

| 3 | Maximum feed size(mm) | 700 | |

| 4 | Size of feeder (length x width)(mm) | 3350×1000 | |

| 5 | Feed capacity (t/h) | 150-400 | |

| 6 | Power of Feeder | 3kw×2 | |

| 7 | Jaw Crusher | Models | 1060 |

| 8 | Maximum feed particle size (mm) | 700 | |

| 9 | Inlet size (length x width)(mm) | 700×1060 | |

| 10 | Processing capacity(t/h) | 150-400 | |

| 11 | Discharge particle size range(mm) | 0-300 | |

| 12 | Power(kw) | 110 | |

| 13 | Weight(t) | 14.35 | |

| 14 | Main belt conveyor | Width/length (mm) | 1200×22450 |

| 15 | Discharge height(mm) | 2950 | |

| 16 | Power(kw) | 15 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 |