Application

The Modular Impact Crusher for Crushing Soft Rock is widely used across various industries due to its efficiency in processing softer materials like limestone, gypsum, and shale. In the construction and aggregate industries, it plays a crucial role in producing high-quality crushed materials for road construction, concrete production, and other infrastructure projects. The crusher effectively reduces soft rock into fine aggregates and gravel, which are essential for making durable concrete, asphalt, and other building materials.

In the mining industry, the Modular Impact Crusher is commonly used for ore processing and production of crushed materials required for processing plants. It helps break down soft rocks into smaller, uniform particles that are easier to handle and refine. This ability is particularly beneficial in applications where soft rocks need to be sized or homogenized for further processing.

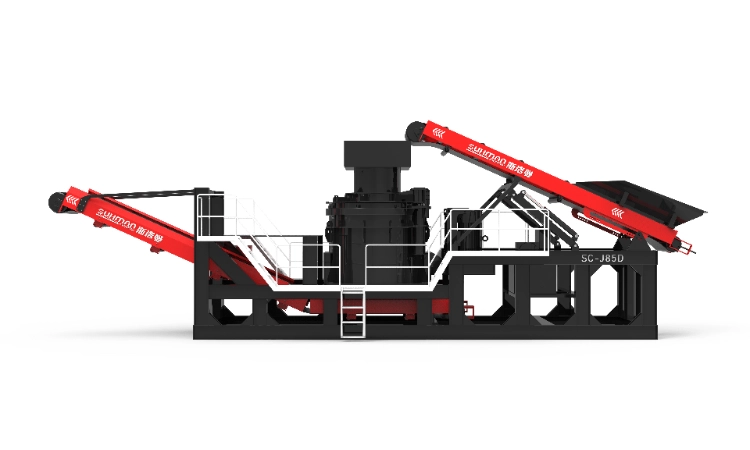

Another significant application of the crusher is in the production of manufactured sand, which is increasingly in demand as natural sand sources become scarcer. The crusher efficiently produces fine, consistent sand ideal for use in construction and concrete manufacturing. Additionally, the modular nature of the crusher makes it highly adaptable for use in recycling operations. It can process construction waste, such as demolition debris and old asphalt, turning them into reusable materials that contribute to sustainable building practices.

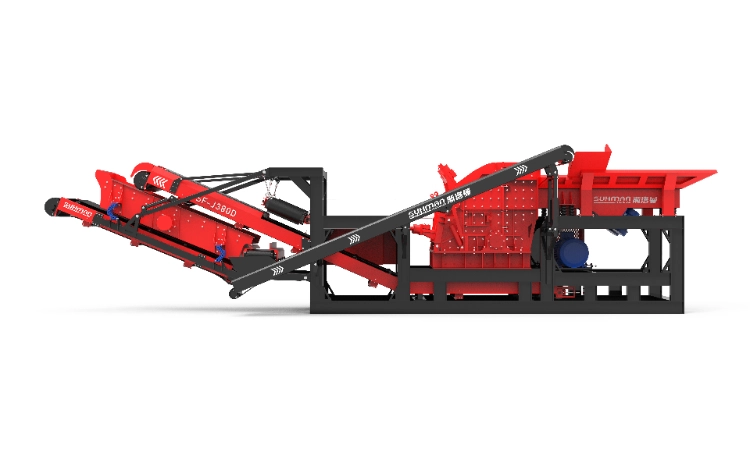

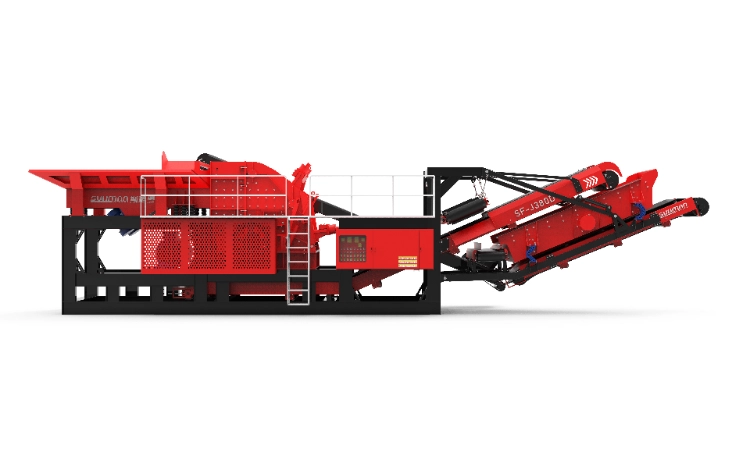

The modular design also allows for easy transport and installation in both permanent and temporary setups, making it an ideal solution for various on-site operations. Whether for small-scale projects or large-scale operations, the Modular Impact Crusher for Crushing Soft Rock delivers high performance and reliability.

Product Parameter

| Parameter | Specification |

|---|---|

| Model | Modular Impact Crusher |

| Material Processed | Soft rock (limestone, gypsum, shale, coal) |

| Feed Size | Up to 500 mm (varies based on model) |

| Capacity | 100-500 tph (varies by model and material) |

| Rotor Speed | 800-1200 rpm (depending on model) |

| Motor Power | 75 kW to 400 kW (depending on model) |

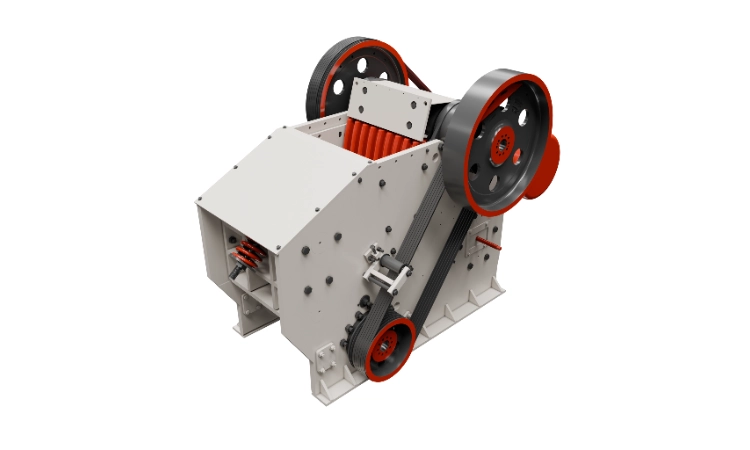

| Crusher Type | Horizontal shaft impact (HSI) |

| Rotor Diameter | 1000 mm to 1500 mm (depending on model) |

| Max Feed Size | 250 mm to 500 mm (depending on model) |

| Product Size | 0-40 mm (adjustable) |

| Discharge Opening Adjustment | Hydraulic or manual adjustment |

| Weight | 15,000 kg to 45,000 kg (depending on model) |

| Overall Dimensions | 6 m x 3 m x 4 m (varies by model) |

| Crushing Chamber Design | Adjustable impact plates or anvils |

| Liner Material | High-chrome, wear-resistant steel |

| Power Supply | Electric or diesel (depending on model) |

| Transportability | Modular design, easy to transport |

| Installation | Quick assembly, no foundation required |

| Maintenance | Easy access to wear parts, low downtime |