Application

The Modular Impact Crusher for Sand Making is highly effective in producing high-quality manufactured sand and fine aggregates for a variety of industries. Its primary application is in the production of sand for construction, where it helps in meeting the growing demand for high-grade aggregates used in concrete production. The crusher efficiently reduces hard and abrasive materials like limestone, granite, and basalt into fine particles that are perfect for use in construction and infrastructure projects.

In addition to construction, the Modular Impact Crusher is widely used in the mining industry for ore processing. It is particularly useful for producing fine aggregates for road construction, pavement, and other civil engineering works. Its ability to process a wide range of materials allows it to serve different sectors, including recycling. The crusher effectively processes construction waste, such as concrete, asphalt, and demolition debris, into reusable fine aggregates and sand. This not only reduces environmental impact but also provides a sustainable way of managing waste material.

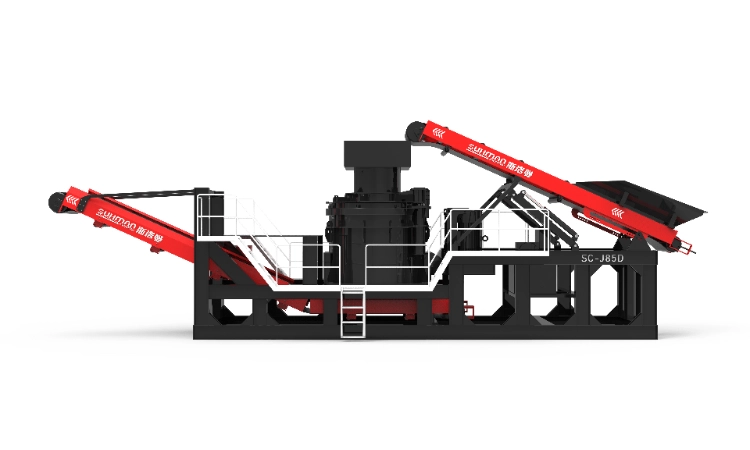

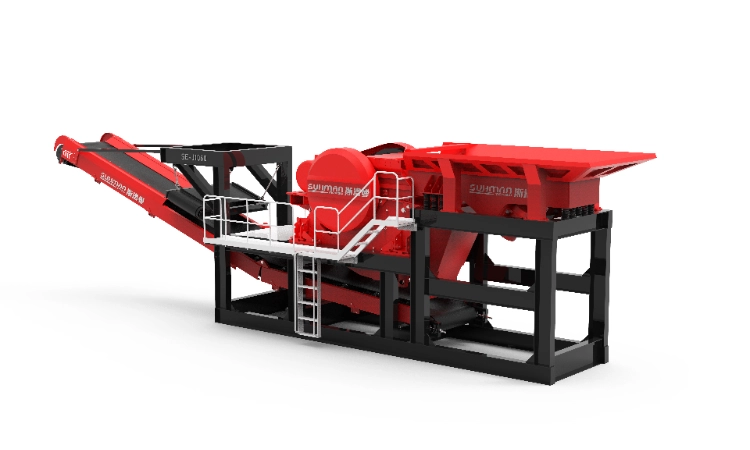

The versatility and modular design of the impact crusher make it ideal for both large-scale and small-scale operations. Its compact size and ease of transport and installation enable its use in remote areas or on-site for temporary crushing needs. The crusher is a reliable solution for meeting the specific requirements of producing high-quality sand and aggregates in various industries, while its modular design allows for customization based on production needs and space constraints.

Product Parameter

| Project | Description | SC-J85D | |

| 1 | Feeding equipment | Hopper volume(m³) | 3 |

| 2 | Maximum feed size(mm) | 50 | |

| 3 | Feed capacity (t/h) | 150-350 | |

| 4 | Power of Feeder | 7.5(kw)×2 | |

| 5 | Impact Crusher For | Models | 85D |

| 6 | Maximum feed particle size (mm) | 50 | |

| 7 | Inlet size (length x width)(mm) | 1540×1000 | |

| 8 | Processing capacity(t/h) | 250 | |

| 9 | Power(kw) | 220 | |

| 10 | Weight(t) | 18 | |

| 11 | Main belt conveyor | Width/length (mm) | 1200×19100 |

| 12 | Discharge height(mm) | 3200 | |

| 13 | Power(kw) | 15 |